Process

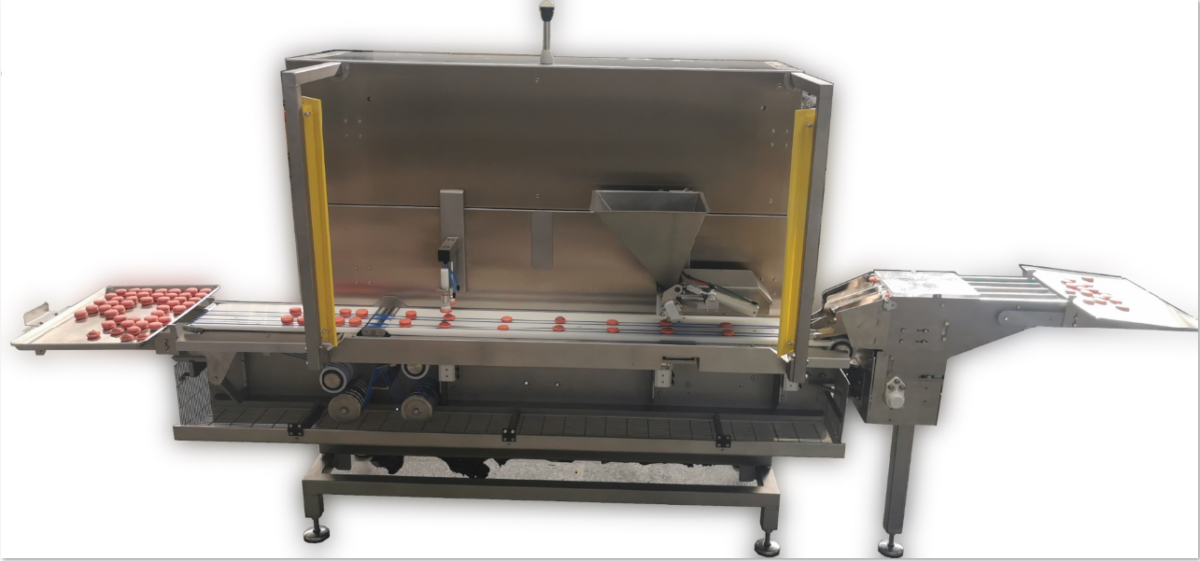

Capper Small

Semi-industrial version for productions with rotatory ovens

PROCYS declines a version of capper adapted to artisanal productions (up to 2400 finished products / hour) for products cooked on baking sheets in a rotary oven. The machine is manually fed after cooling the products on the racks.

The main objective of this line is to make macarons by removing manual and repetitive operations.

It is a compact machine, flexible with quick flavor changes, easy to manage, easy to clean, allowing to increase production volumes.

How does it work ?

The following operations are done automatically:

01

Manual feeding with shells/biscuits

02

Products alignment

03

Preparing rows and lanes

04

Tilting of 1 lane out of 2

05

Dosing and capping

06

Manual pick-up of macarons/sandwich biscuits

A dedicated solution

Discover all the benefits of our customizable solutions for your production system.

PROCYS adapts to your specifications and offers customized solutions.

Capper Small sandwiching machine – semi industrial version

What are the benefits ?

Why PROCYS ?

Innovative prodution system

Flexible production system

- A team with a solid experience at your disposal

- Tailor-made solutions fully adapted to your needs

- The specialist in the automation of macaron lines

- Automation of your process by keeping your artisanal recipes

- Limitations of manual operations

- Ergonomic workstations

- Increases production volume

- Simplifies your process

- Adaptation to your production tools

- Possible format change

- Several toppings possible

- Arrangement in blisters or collection stations at the exit of the machine